Your Trusted One-Stop Automotive Fastener Manufacturer with 13 Years of Global Expertise -QEEPEI

Founded in 2013, QEEPEI Group is a leading provider of automotive fastener solutions, integrating R&D, manufacturing, and global trade. Our 8,000㎡ headquarters is equipped with advanced injection molding machines and intelligent quality inspection systems. We are certified by ISO/TS 16949, SAE, CE, RoHS, REACH, and 20+ other international standards.

Trusted by over 60 automotive brands worldwide, we offer OEM/ODM services tailored to your needs—from custom-printed clips to various shapes and styles. We are committed not only to product quality but also to building long-term partnerships. Our experienced sales and support teams ensure fast response and complete customer satisfaction.

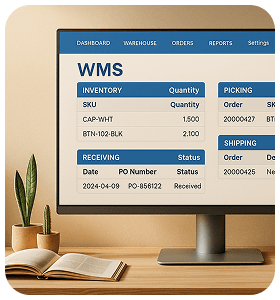

- 2,000+ SKUs in stock, covering a wide range of vehicle models

- 24-hour shipping for regular items to shorten delivery times

- Smart warehousing with categorized storage and traceable labeling

- Real-time stock data, fully integrated with our sales system

Smart Inventory Fast Delivery

We maintain a well-organized inventory system to ensure that every automotive fastener and clip is always in stock. With efficient logistics and streamlined order processing, we guarantee quick dispatch and on-time delivery to keep your business running without delays.

Environmentally friendly materials

We always believe that true quality is not only reflected in product performance, but also in the responsibility to the environment and society. Our commitment to environmental sustainability and eco-friendly practices is evident in every aspect of our business.

100% environmentally friendly raw materials

Focus on using new PA, PP, POM environmentally friendly materials to eliminate recycled materials, ensure non-toxic and odorless, and stable performance.

Complete certifications

Passed international environmental certifications such as RoHS, REACH, SGS, etc., and can provide complete test reports, worry-free global access.

Environmental protection + durability

Green manufacturing, taking into account high strength, aging resistance, high temperature resistance and other properties, meets the strict standards of the automotive industry.

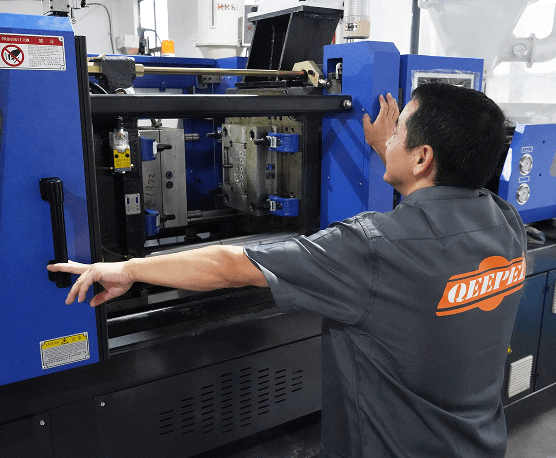

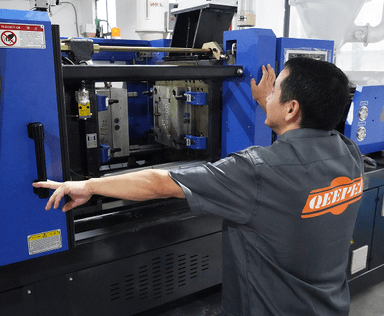

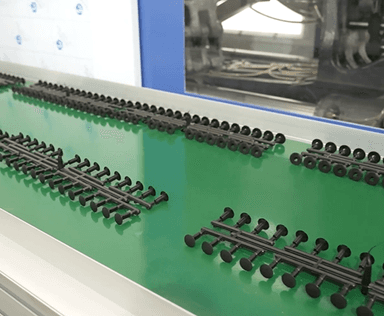

Advanced Manufacturing, Consistent Quality

We always insist on relying on advanced equipment to continuously improve manufacturing efficiency and car clips quality. Through intelligent and standardized production systems, we provide customers with highly stable and efficient buckle product supply services.

Advanced injection machines

With 5 high-precision injection molding machines and automated production equipment, covering the full process manufacturing capabilities from precision injection molding to automated assembly.

Driven by Technology Powered by People

Extensive model development capabilities

We have over 4,000 years of experience in designing and manufacturing fasteners, covering mainstream vehicle models and diverse requirements.

Professional R&D Team

Led by senior engineers, focusing on the design of snap-in structures and material optimization.

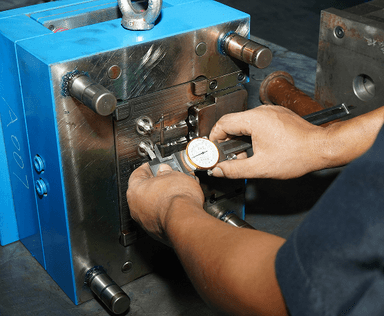

Efficient mold development

Own mold workshop, quick response to customized demands

Cross-departmental collaboration

seamless integration of R&D, manufacturing, and quality control to ensure the efficient progress of the project

Continuous technological innovation

Allocate dedicated research and development funds each year, and continuously optimize process and structural designs

We have an experienced R&D team and an efficient manufacturing team that works collaboratively, dedicated to providing global customers with high-quality, customized automotive fastener solutions.

Based on over 10 years of industry experience, we continuously innovate processes, optimize mold designs, and achieve rapid development, efficient mass production, and stable delivery. With a professional, efficient and rigorous attitude, we create higher value for each customer.

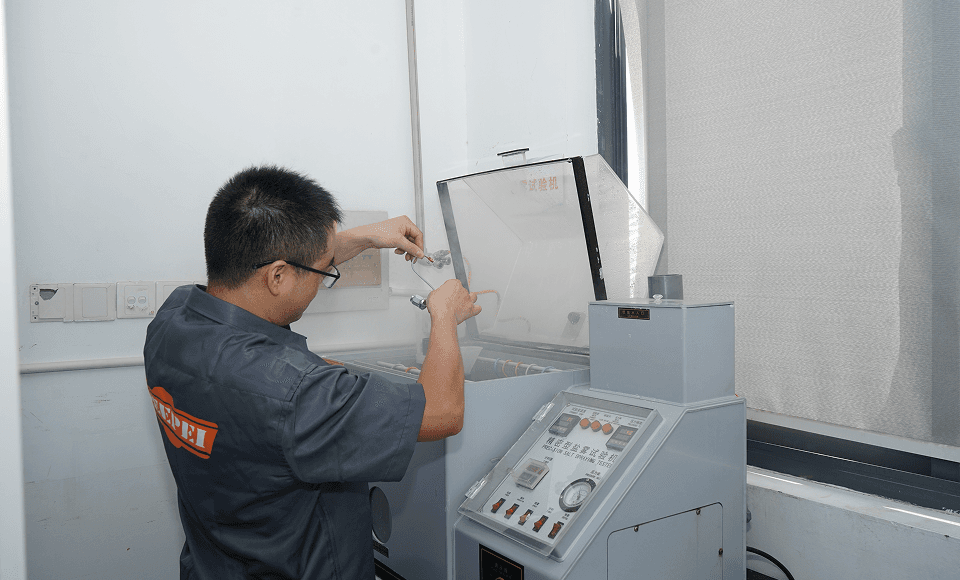

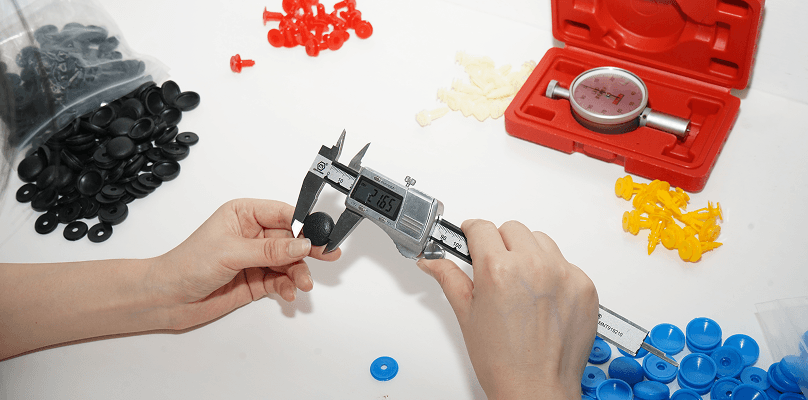

Quality control

We have always regarded product quality as the lifeline of our enterprise's development. We have established a complete process and multi-dimensional quality control system to ensure that every product meets international standards.

Continuously use new materials: All products are produced using brand-new raw materials. We do not use recycled materials. The quality is more stable

Continuously use new materials: All products are produced using brand-new raw materials. We do not use recycled materials. The quality is more stable Full-process quality control: From raw material entry to finished product shipment, multiple inspection procedures are implemented.

Full-process quality control: From raw material entry to finished product shipment, multiple inspection procedures are implemented. Strict standard implementation: Fully comply with the ISO/TS 16949 quality management system, and conform to international standards such as SAE, CE, and ROHS.

Strict standard implementation: Fully comply with the ISO/TS 16949 quality management system, and conform to international standards such as SAE, CE, and ROHS. Laboratory professional testing: A separate testing center is available, capable of conducting tests for high/low temperatures, impact resistance, tensile strength, and aging resistance, among others.

Laboratory professional testing: A separate testing center is available, capable of conducting tests for high/low temperatures, impact resistance, tensile strength, and aging resistance, among others. Combination of spot checks and comprehensive inspections: 100% comprehensive inspection of key areas to ensure consistency in each batch of products Traceability management mechanism: Complete records are established for each batch of products to ensure that problems can be traced and the handling process can be closed-looped.

Combination of spot checks and comprehensive inspections: 100% comprehensive inspection of key areas to ensure consistency in each batch of products Traceability management mechanism: Complete records are established for each batch of products to ensure that problems can be traced and the handling process can be closed-looped.

What can we do for you?

We always believe that true quality is not only reflected in product performance, but also in the responsibility to the environment and society.

Submit in

30 Seconds

Get a Quotation in 2 Hours